You may be wondering, What exactly are fiber lasers, and how will they change the world? Here, we take a deep dive into fiber lasers and the world of lasers in general to answer this question. We’ll cover fiber laser technology, applications, which manufactures fiber lasers, what kind of companies use fiber lasers, and much more!

If you want to buy, by the end of this article, you’ll know everything you need about laser fiber lasers buy to use in your industry.

How does it work?

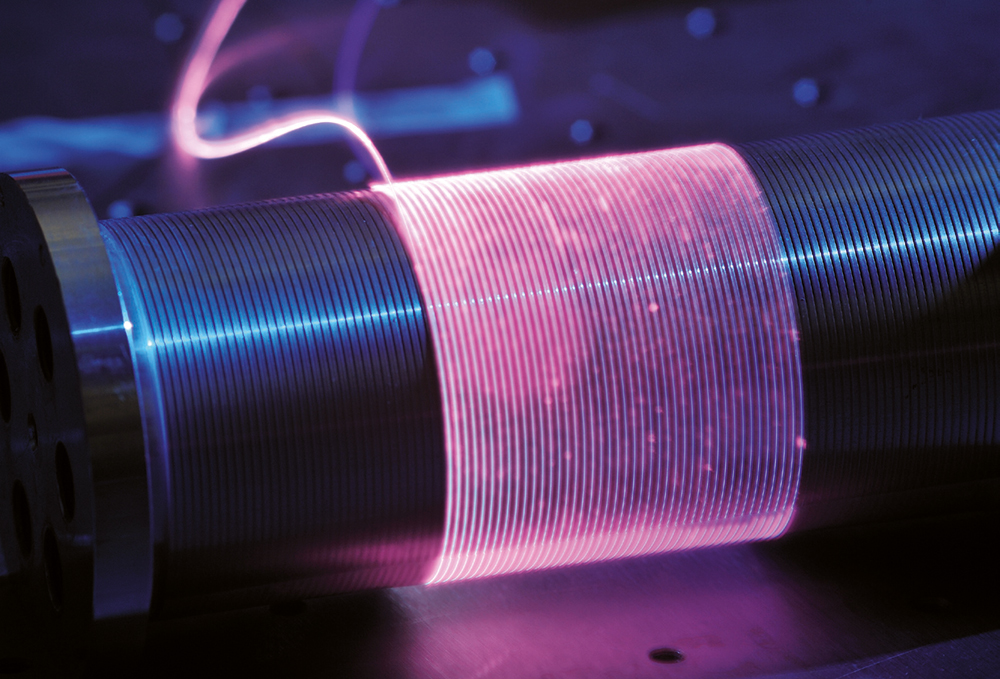

Unlike today’s solid-state lasers, which emit light through a semiconductor material, fiber laser technology is entirely optical. This allows them to focus coherent beams on microscopic targets. The entire resonator — a finely tuned cavity in which light bounces back and forth before exiting — can be made from photonic crystals or bulk optics such as glass rods or lenses.

Fiber lasers don’t just transmit information for telecommunication networks. They also have found applications in spectroscopy, and industrial processing as cutting tools, welding torches, and high-powered pumping systems, where intense energy densities are needed but other sources (such as electrical arcs) would be too hazardous.

What can be done with fiber lasers?

Fiber lasers could help with everything from scientific research to defense projects to consumer electronics. We are talking about an average laser that is about 20 times as powerful, operates at one-fifth of the power, and generates light in a much narrower range than its previous predecessors.

Additionally, these new lasers can be tuned by computer to work at specific frequencies. This tuning allows scientists more control over how they shape materials with light. For example, it has been suggested that this will create new opportunities for 3-D microelectronics fabrication and engineering of novel biosensor configurations without destroying their structure or function when capturing a sample analyte such as DNA.

Results vs. expectations?

Today’s fiber lasers offer a lot more features than early lasers did. This is because research and development are continuing to improve fiber laser technology in so many ways, from beam power to how well it can transmit heat, among other things. But even though fiber lasers are a newer type of laser than some others, they still have two major advantages over them: lower maintenance and less safety risk for workers.

Because these aspects take up so much space on manufacturing budgets now and in the future, manufacturers will be making more choices towards using fiber lasers. We foresee that one day all factories will use these because it’s more cost-effective to purchase fewer high-quality devices that work better and have fewer maintenance risks than many medium-quality devices on hand.

Are there any risks?

In a word, no. But fiber lasers have some downsides when deciding on an appropriate machine. The most obvious downside is the cost, as fiber laser cutting equipment can cost anywhere from $20K and above per set-up, depending on size and duty cycle. This can make buying a single machine prohibitive for many companies that don’t have extensive budgets for capital expenditures.

A second potential issue is setup time — most lasers are designed to work at high power levels, but this requires close supervision from experienced personnel.