Congratulations, your product is finally manufactured! Or at least thoroughly planned to be. The final step is the piece’s very own signature or marking. The importance of marking in product tracing and quality assurance during the whole product lifecycle is growing continuously, and the requirements for accuracy and constancy of marking cannot be underestimated.

The piece can be marked easily with a paper sticker or ink, and in some rare circumstances, this method may be justified. But if the marking is expected to last for as long as your part is used, you would need something more solid and reliable. One of the best and optimal choices of marking technology is dot peen marking. Read more here…

How can dot peening be useful?

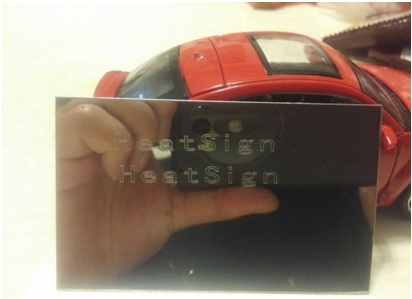

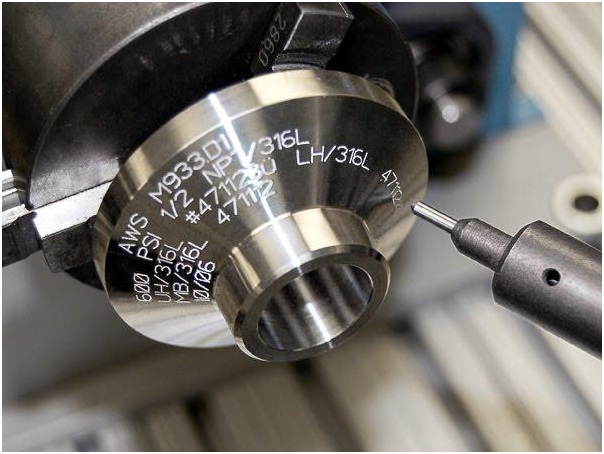

Dot peen marking is used to engrave information on a wide range of metal surfaces as well as several non-metal. This information may include text (letters, symbols and numbers) and graphics like logos or 2D matrix codes. This means dot peen marking can serve both brand recognition and traceability needs. As it takes seconds to engrave, the dot peen technology helps automate the marking process not sacrificing the quality and precision of the engraved information.

As a result – highly permanent man- and machine-readable marks for the whole manufacturing line such as:

- company or brand name

- logos

- part numbering

- date, a lot, batch or shift codes

- and others

How does it work?

The technology employs a carbide pin that deepens into the material and forms the requested mark with a sequence of small dots. Dot peen marking easily masters hard surfaces, making the technology one of the favorites in aerospace, metalworking and automotive industries. Yet the pressure of the pin onto the surface is very moderate and completely eliminates any possible damage to the parts marked. This allows the technology to handle more delicate materials like plastics, wood, ceramics, cardboard.

In-house engraving with a dot peen marking machine

Although the process of dot peen engraving may seem complicated, the new generation dot peen marking machines make it possible to perform the marking of your products without any third-party subcontractors involved, in-house.

There is a vast variety of dot peen marking machines depending on the special demands of the client, including machines with the electric or pneumatic operation, machines with their own touchscreen and software, portable machines and handheld ones. No specially trained staff, exquisite tools or high investments needed. This makes dot peen marking suitable for in-house use in manufactures of any size, even in small or mid-size enterprises. One should though consider consulting the provider before purchasing the machine to ensure it fully suits the needs of the enterprise.

The quality and high permanent marking by dot peening method are often compared to those produced by laser marking, that is in some ways a more sophisticated and flexible technology. Yet the cost-effectiveness of the first makes it a reasonable choice for enterprises and manufacturers in the fields of metal processing, agricultural machinery, construction equipment, oil and gas, electronics, transportation, military, and others.