The transformation of industrial operations has accelerated under the umbrella of Industry 4.0. Smart factories, interconnected devices, and intelligent data analytics have become the backbone of modern production.

Yet, in many facilities, the foundation of control systems still relies on traditional methods. One of the most widely employed approaches is Ladder Logic Programming for Programmable Logic Controller (PLC) systems, a language that has been central to PLCs for decades.

The continued reliance on Ladder Logic Programming in industrial automation presents both challenges and opportunities as industries shift toward modern, connected environments.

Why Ladder Logic Still Matters

Despite the rise of advanced programming languages and integrated platforms, Ladder Logic Programming remains significant due to its simplicity, reliability, and close resemblance to electrical schematics.

Plant operators, technicians, and engineers often find it easier to interpret and troubleshoot, as the diagrams mirror the wiring systems of relays and switches. For industries where downtime translates into substantial losses, this intuitive structure provides reassurance.

Moreover, PLCs governed by ladder logic are already embedded across countless manufacturing plants, energy facilities, and production units. Replacing these systems outright is rarely feasible, both from a cost and operational standpoint. Instead, industries are exploring ways to incorporate these legacy systems into the broader framework of Industry 4.0.

Integrating Legacy Systems with Modern Automation

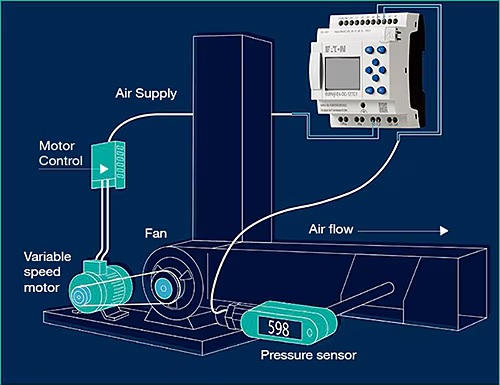

Bridging the gap between traditional PLCs and advanced automation involves a thoughtful integration process. Legacy devices governed by Ladder Logic can be connected with Supervisory Control and Data Acquisition (SCADA) systems or integrated into Industrial Internet of Things (IIoT) platforms. Through gateways and communication protocols, older equipment can transmit valuable data to central networks, enabling real-time monitoring and analytics.

This approach ensures that businesses do not discard decades of investments in equipment. Instead, they can deploy modern technologies while employing existing infrastructure. Incorporating sensors, edge computing devices, and cloud-based monitoring enables predictive maintenance, energy optimization, and improved quality control, all without dismantling reliable systems already in place.

Advantages of Hybrid Deployment

The hybrid model of employing ladder logic programming alongside modern automation brings several advantages. First, it maximizes operational continuity. Operators already skilled in ladder-based systems can continue to manage processes while new technologies are phased in.

Second, it reduces capital expenditure by extending the life of legacy electrical instruments and control devices. Finally, it provides a gradual transition toward digitalization, minimizing disruption across the supply chain.

Additionally, modern analytics tools can process data generated by Ladder Logic-driven devices, translating it into actionable insights. This allows decision-makers to optimize energy use, reduce equipment downtime, and enhance throughput efficiency. The combined effect is a more resilient operation capable of adapting to market shifts and technological advancements.

Role of Standardization and Safety

For industries adopting a hybrid approach, safety and standardization remain paramount. Ladder logic programming offers a predictable and structured framework, ensuring processes operate within strict parameters.

When integrated with advanced automation, additional safeguards such as cybersecurity measures, compliance checks, and real-time alarms can be incorporated. This combination reinforces the integrity of operations, protecting both equipment and personnel.

Standardization across protocols and devices also plays a critical role. Interoperability ensures that legacy systems and modern solutions communicate seamlessly, allowing factories and facilities to scale their automation capabilities without creating isolated silos.

The Value of Partnering with Reputable Energy Brands

For businesses navigating this transition, aligning with reputable energy brands offers significant advantages. These partners provide not only reliable equipment and devices but also expertise in deploying hybrid automation systems. By incorporating solutions backed by trusted providers, organizations gain access to advanced technologies while ensuring compliance, safety, and long-term efficiency.

Working with established partners also minimizes risks associated with system upgrades. Their proven track record ensures that integration processes are smooth, equipment compatibility is verified, and operational disruptions are reduced. Energy efficiency and sustainability define competitiveness; such collaborations help industries remain resilient and future-ready.