Prototyping is an essential part of automotive headlamp design and manufacturing. It allows the verification of optical performance, mechanical structure, and also manufacturability before full-scale production. The automotive prototype development process typically begins with computer-aided design modeling to define the lamp styling and internal geometry. Rapid prototyping techniques such as 3D printing or CNC machining are then utilized to create the physical prototypes for testing.

These test parts validate the photometric output and the structural integrity through vibration, thermal, and lifecycle assessments. Refining the prototyping approach enables the automakers and suppliers to reduce the development time and cost for the innovative headlamps with improved safety and styling.

Auto Head Lamps Production and Prototyping

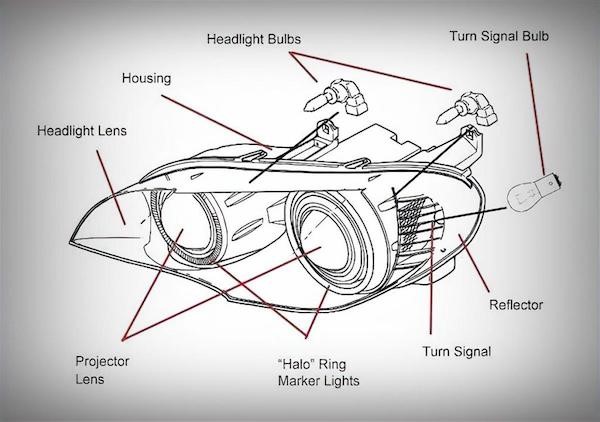

The production of auto headlamps requires the assembly of various components, each serving a distinct function with specific material needs. The primary components include:

- Reflector Cups: These components, often crafted from polycarbonate or coated metals, focus on reflecting light efficiently.

- Housing: It safeguards the internal elements and usually comprises durable materials such as ABS plastic.

- Light Guide: This part directs light effectively using transparent polymers like polycarbonate.

- Bezel: As the front cover, bezels typically utilize PMMA for its clarity and visual appeal.

- Lens: Made from either glass or transparent plastics, the lens is crucial for focusing and shielding the light source.

See this table for better comprehension and readability.

| Component | Suitable Material |

| Reflector Cups | Polycarbonate or Coated Metals |

| Housing | ABS Plastic |

| Light Guide | Clear Polymers such as polycarbonate |

| Bezel | PMMA (Poly(methyl methacrylate)) |

| Lens | Glass or Clear Plastics |

The Design Concept of Auto Head Lamps & Its Prototyping

The design of automotive headlamps focuses on maximizing illumination while meeting the regulations. Automotive prototypes help evaluate the lighting concepts by conducting several tests before going into mass production. Optical testing refines the lamp housing, reflective surfaces, bulb placement, and diffusers to optimize the light projection according to defined patterns that consider the beam distance and width.

Head Lamp Design

The design process of auto headlamps integrates optical engineering, material science, and compliance with automotive regulations.

- Optical Details and Undercuts: Achieving precision in the optical components, including lenses and reflectors, is crucial. These elements require design optimization for effective light distribution to ensure visibility while preventing glare to other drivers. Utilizing automotive prototypes enables designers to explore various shapes and angles, ultimately finding an equilibrium of aesthetics and functionality.

- Durability and Reliability: The selection of materials for headlamp parts must consider their ability to endure extreme conditions such as high temperatures, vibrations, and impacts. Materials like polycarbonate and coated metals provide the necessary durability for reflector cups and housings. Through automotive prototyping, evaluating these components’ longevity and effectiveness becomes possible.

- Heat Dissipation: The headlamp enclosure design must account for the heat dissipation from the light source through the conduction and convection techniques. Prototyping validates the thermal performance before finalizing the housing geometry and the ventilation design. The quality of plastics used for lens and housing also requires UV stabilization and prevents yellowing or cracking over time.

By meticulously balancing these aspects, the automotive prototype paves the way for aesthetically pleasing, robust, and efficient headlamps in real-world conditions.

Auto Head Lamp Manufacturing and Prototyping Methods

CNC Machining

In auto headlamp manufacturing and prototyping, CNC (Computer Numerical Control) machining plays a pivotal role, particularly in crafting fixtures, reflectors, and bezels with high precision. This advanced manufacturing technique is employed to achieve superior surface quality, which is crucial for both aesthetic appeal and functional integrity of headlamps. CNC machining delivers finished surfaces with an impressive tolerance of ± 0.05mm, accommodating even the most intricate optical details with a minimal machining radius of R0.1mm.

Furthermore, the machined surface roughness is finely controlled to Ra0.2μm, with the option of mirror polishing to an ultra-fine Ra0.02μm, ensuring optimal light reflection and distribution in the headlamp assembly.

Injection Molding

The manufacturing and prototyping automotive headlamps via injection molding is a sophisticated process, demanding precision and a detailed understanding of material properties. Common materials used include PMMA (Acrylic), known for its high light transmittance and chemical resistance; ABS and PC/ABS alloys, offering significant heat resistance; PBT (Polybutylene Terephthalate) for its mechanical and thermal stability; PET (Polyester) for its processing capabilities; Nylon for high-strength applications; PEI (Polyetherimide) for high-temperature resistance; and BMC, a thermosetting material, for headlight reflectors.

A case study illustrates the complexity of this process. For instance, PP+TD20 material is used for headlight casing, where PP provides the base, and TD20 (20% talcum powder) enhances rigidity. The part must be free from surface defects and meet precise assembly requirements. Its complex shape includes undercuts and symmetrical features. The 1+1 cavity mold with a cold runner system is tailored for mirrored parts of left and right headlights, avoiding lateral core-pulling mechanisms.

Multicolor molding technology aligns with the automotive industry’s evolving standards, requiring seamless headlamp aesthetics and functionality integration. This involves using materials like BMC for bases and PMMA, PP, and ABS for shells. For dual-color headlights, precise alignment of screw center distances with the mold is imperative.

3D Printing

3D printing offers unparalleled flexibility and rapid iteration capabilities, particularly in automotive headlamp prototyping. This technology, employing methods like Stereolithography (SLA) and Selective Laser Sintering (SLS), allows designers to create complex geometries unachievable through traditional manufacturing. Intricate light patterns and customized housing shapes can be prototyped swiftly for headlamps.

However, 3D printing is primarily suitable for automotive prototypes rather than mass production. Its utility in headlamp development lies in its ability to rapidly prototype and test design variations, material properties, and light dispersion patterns, thus accelerating the innovation cycle while maintaining high precision and customization.

Conclusion

Automotive headlamp prototyping is a critical and intricate process for developing efficient, safe, and aesthetically appealing lighting solutions. Manufacturers can explore and refine headlamp designs by employing advanced techniques like CNC machining, injection molding, and 3D printing, ensuring compliance with stringent regulations and performance standards. These methods facilitate precisely shaping automotive prototypes, optimal light distribution, and durability testing under various conditions.

The flexibility of automotive prototyping accelerates innovation, allowing for the meticulous balancing of functionality, safety, and design aesthetics. Ultimately, this process not only streamlines the development of automotive headlamps but also significantly enhances their quality and reliability, meeting the ever-evolving demands of the automotive industry.