An electromechanical device that is used to transfer power and signals from a motionless or we can say stationary point to a structure that is having rotational process is called the Electrical Slip Ring. The Electrical Slip Ring can be used in any type of electromechanical system. But the thing that important is the system must require unrestrained, intermittent and also a dynamic rotation. The Electrical Slip Rings are also widely used in improving the mechanical performance of the system. There are several leading ring manufacturers that provide technology that is ATEX certified and IECEx certified.

An Electrical Slip Ring Working

The Slip Ring helps in transferring continuous electrical signals from a stationary point to the rotating sections of the system. There are several names through which one referred the Electrical Slip Rings like the rotary electrical interface, collector, swivel, and rotator joint and several others. Well, we can see that there are several names but the product is the same. Sometimes the Electrical Slip Rings are also known as commutators. Commutators are specialized devices that are created to get used on direct current motors and generators. Electrical Slip Rings are continuous in nature while on the other hand, the commutator is segmented.

Maintenance of Electrical Slip Rings

In order to get a long service life, it is important to provide regular and appropriate maintenance to the Electrical Slip Ring. When you purchase the Electrical Slip Ring you will get a brochure that will contain all the instructions required to maintain it.

Signals transmission through Electrical Slip Rings

You must have seen the electrical control devices or monitoring device is transferring the signals to other systems. Similarly, the Electrical Slip Rings are considered as a reliable product that can help in completing the same task. The design of Electrical Slip Ring circuit is like a slide having two or more brush contacts or Electrical Slip Rings

Types of signals that can be transmitted through Electrical Slip Rings

In the below section we have given some of the types of signals that can be transmitted through the Electrical Slip Ring unit to other systems. The examples are:

- Video

- Communications

- Serial Links RS232/RS485

- Superimposed signals onto 1kV power circuits

- Data – PLC 115.2 kBaud

- ESD signals

- Fire & Gas

- Fiber optic

Testing of Electrical Slip Rings

All the sleeping units get tested before getting dispatched. While testing the Electrical Slip Rings get checked for continuity, insulation resistance, dielectric strength, torque, and rotational tests.

Dispatch

It is important to maintain the Electrical Slip Rings properly. Furthermore, during transporting the products from one area to another, it is essential to check that the Electrical Slip Rings are properly packaged or not.

Why Electrical Slip Rings are used in the motor?

Flip rings are also known as rotary electrical joints, electric swivels, and collector. This is because Electrical Slip Rings are the devices that are used to transfer signals, power, current and data from a stationary compound to rotator compound. The design of the Electrical Slip Rings always depends upon how the user going to consider it for the application. The basic application of Electrical Slip Rings is the transfer of data.

Advantages of Electrical Slip Rings:

Following are the advantages of using the Electrical Slip Rings:

- Increased reliability

- Extremely low electrical noise

- LESS than 1 milliohm resistance

- Sealed ball bearing construction

- Durable, compact and low cost

- In stock availability

- Long life

- Made in the U.S.A.

Advantages of Electrical Slip Rings in Motors:

- High Starting torque with the low beginning current. The most extreme beginning can be achieved in the Electrical Slip Ring engine contrasted with squirrel confine engine by embeddings an outer opposition in each period of the rotor circuit and cutting the obstruction during the beginning

- Speeds can be balanced on account of Electrical Slip Ring (wound rotor) enlistment engine by embeddings an opposition. Henceforth Electrical Slip Ring motors are considered as factor speed motors.

- Electrical Slip Ring motors have high over stacking limit, smooth speeding up under substantial burdens and no strange warming during the beginning

Disadvantages of Electrical Slip Rings in Motors:

- Initial and support cost is more contrasted with squirrel confine engine since nearness of Electrical Slip Rings, brushes, short-circuiting gadgets and so on.

- Speed guideline is poor when worked with outside protections in the rotor circuit

- Efficiency and power factor of Electrical Slip Ring engine is lower contrasted with squirrel confine enlistment engine

- Lower control factor at the light loads

- Sensitivity to changes in supply voltage

Types of Electrical Slip Rings:

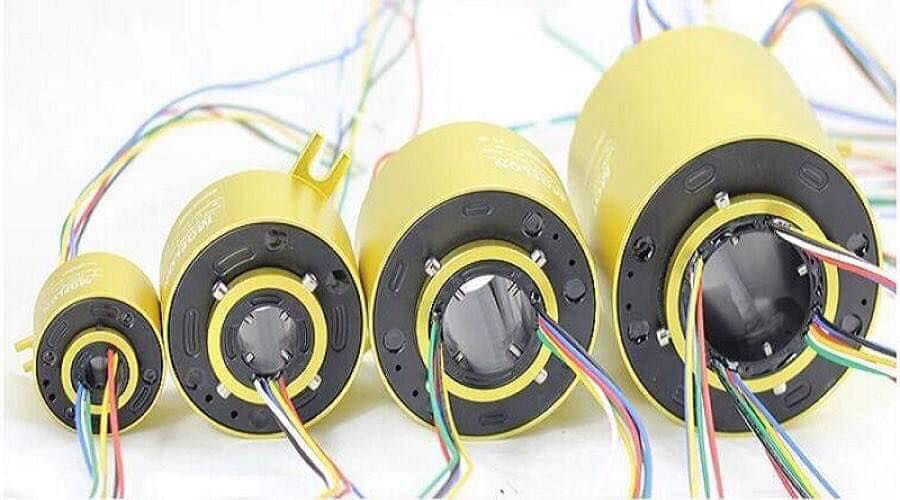

Well, the Electrical Slip Rings are available in several shapes and sizes. But commonly there are three types of Electrical Slip Rings namely Mercury-wetted Electrical Slip Rings, Pancake Electrical Slip Rings, and Wireless Electrical Slip Rings. Now take a look over each briefly:

Mercury-wetted Electrical Slip Rings

Mercury-wetted Electrical Slip Rings are famous for their low resistance and also these are stable in nature. The connection of Mercury-wetted Electrical Slip Rings is basically used in Different principals. While using the Mercury-wetted Electrical Slip Rings, it is important to have proper care because Mercury is a toxic substance that is necessary to be handled carefully. In case the Mercury-wetted Electrical Slip Ring gets used in food manufacturing or processing, pharmaceutical equipment, or any other section where the result may be serious or contaminated then precious metal contacts should be chosen first.

Pancake Electrical Slip Rings

Pancake Electrical Slip Ring is another Type of Electrical Slip Ring. In this type, the conductors are arranged on a flat disc as concentric rings centered on a shaft that is rotating in nature. Furthermore, talking about the configuration then the Pancake Electrical Slip Rings have greater weight and volume as compared to other circuits.

Wireless Electrical Slip Rings

The last type of Electrical Slip Rings is Wireless Electrical Slip Rings. The fact that makes the Wireless Electrical Slip Rings different is that they do not depend upon the typical friction based metal and methods used in carbon brush contact. The transfer of both power and data in the Wireless Electrical Slip Rings gets done through a magnetic field. In simple words, we can say that the Wireless Electrical Slip Rings are the upgraded versions of Traditional Electrical Slip Rings.