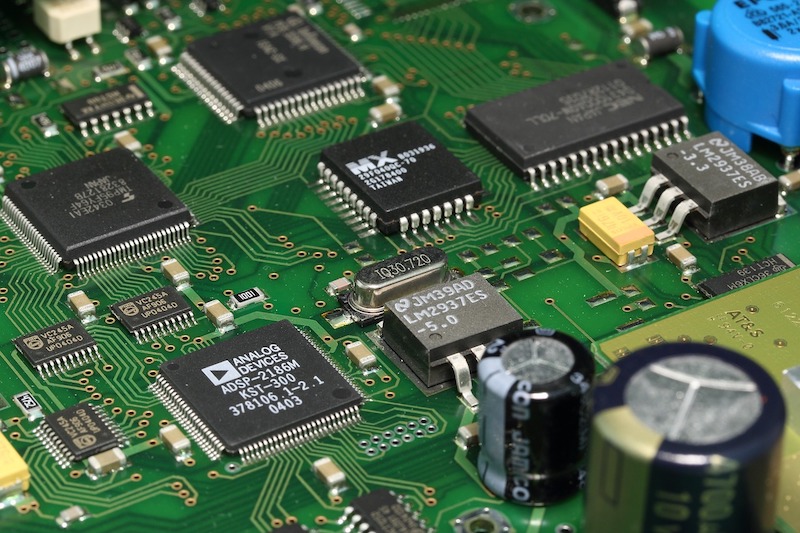

In the dynamic realm of electronics, one of the critical decisions during PCB assembly is choosing between through-hole and surface mount technologies. Each method has its advantages and disadvantages, influencing the performance, cost, and overall functionality of electronic devices. In this blog post, we’ll delve into the nuances of through-hole and surface mount technologies, helping you make an informed decision for your PCB assembly needs.

Understanding Through-Hole Technology

Through-hole technology (THT) has been a staple in PCB assembly for decades. This method involves mounting electronic components by inserting their leads through holes in the PCB and soldering them on the opposite side. This process provides robust mechanical connections, making through-hole components less susceptible to mechanical stress and vibration.

The key advantages of through-hole technology include:

- Mechanical Strength: Through-hole components offer excellent mechanical stability, making them suitable for applications exposed to physical stress.

- Repair ability: When a through-hole component fails, it can be easily replaced or repaired without specialized equipment.

- Heat Dissipation: Through-hole components can handle higher levels of heat without damage, making them suitable for applications with high-power requirements.

https:/www.pcbasic.com/blog/surface-mount-vs-through-hole.html

Exploring Surface Mount Technology

Surface mount technology (SMT) emerged as a response to the demand for smaller, lighter, and more efficient electronic devices. Unlike through-hole components, SMT involves attaching components directly to the surface of the PCB. This method eliminates the need for holes, allowing for a more compact design.

The advantages of surface mount technology include:

- Space Efficiency: SMT components are smaller and lighter, allowing for the creation of more compact and lightweight devices.

- Automated Assembly: SMT is conducive to automated assembly processes, leading to faster and more cost-effective production.

- Signal Integrity: The absence of holes reduces parasitic capacitance and inductance, improving the signal integrity of the circuit.

For a detailed comparison between through-hole and surface mount technologies, check out informative posts by PCBA manufacturer experts.

Making the Decision: Through-Hole vs. Surface Mount

The choice between through-hole and surface mount technology ultimately depends on the specific requirements of your project. Consider factors such as size constraints, production volume, and the level of mechanical stress your device will endure. Many modern electronic devices use a combination of both technologies, known as mixed technology assembly, to optimize performance and manufacturing efficiency.

If you’re looking for a reliable PCBA manufacturer with expertise in both through-hole and surface mount technologies, PCBA manufacturer is a trusted partner. Their commitment to quality and innovation makes them a go-to choice for businesses seeking high-performance PCB assemblies.

In conclusion, the decision between through-hole and surface mount technology requires a careful evaluation of your project’s unique needs. By understanding the strengths and weaknesses of each method, you can make an informed choice that aligns with your goals for performance, cost, and overall efficiency.