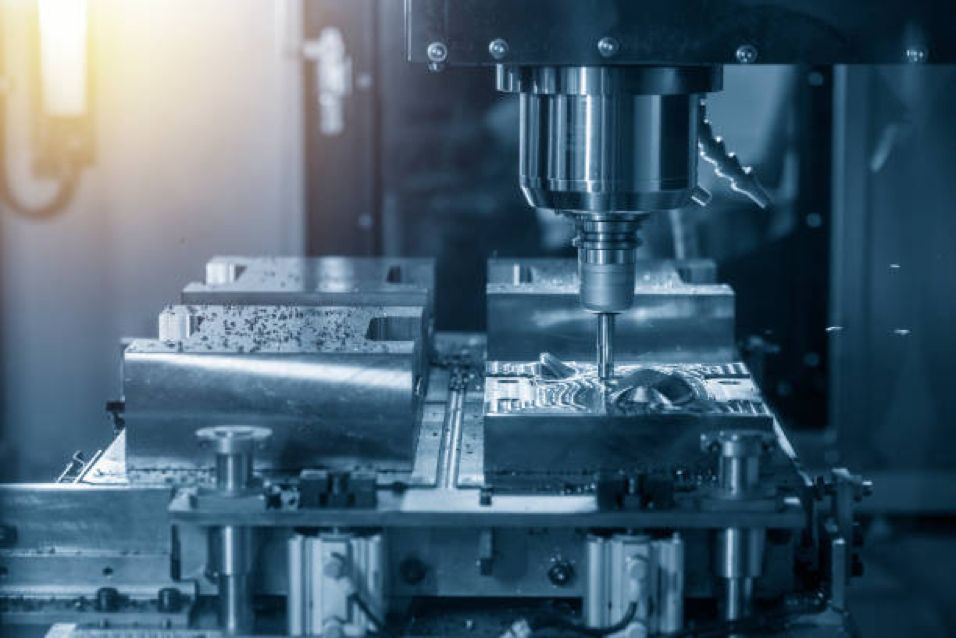

Milling is a manufacturing process that involves the removal of material by means of an abrasive tool. The materials removed are generally small pieces, called chips. In CNC milling, these chips are created by a rotating cutting tool that moves in a circular pattern around a stationary workpiece. There are many important things to know about this process if you plan on using it in your business or workshop. Here are just a few of them.

CNC Milling Popularity Is Set To Increase

It’s no secret that the manufacturing industry has been under pressure in recent years. To stay competitive, manufacturers need to find ways to increase productivity while reducing costs. One way they’re doing this is by investing in CNC milling machines. CNC milling is a form of computer-aided manufacturing (CAM) that uses computer-controlled tools to remove material from a workpiece. This process is more efficient and accurate than traditional methods, and it produces parts with a high level of precision. As a result, CNC milling is becoming increasingly popular among manufacturers. In fact, the global CNC milling market is expected to grow from $6.3 billion in 2020 to $8.5 billion by 2025, at a CAGR of 6.2%. This growth is being driven by factors such as the need for increased accuracy and efficiency, the ability to produce complex parts, and the trend toward miniaturization. With so many benefits, it’s no wonder that CNC milling is set to become even more popular in the years to come.

CNC Milling Technology Will Undergo Improvement

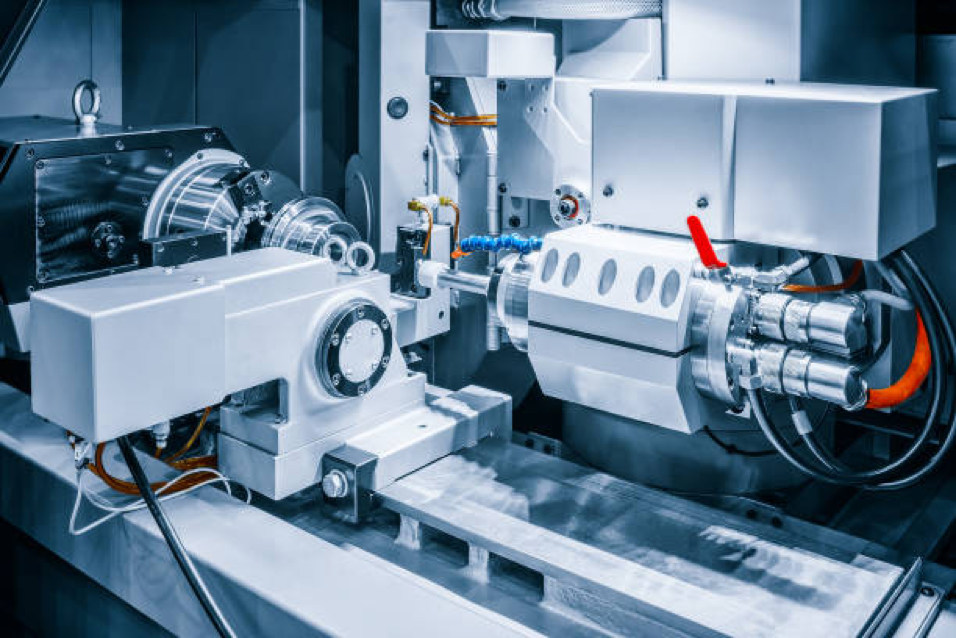

CNC milling technology has revolutionized the manufacturing process, providing a more precise and efficient way to create parts and components. However, as with any technology, there is always room for improvement. In the coming years, we can expect to see further advances in CNC milling technology. One area that is likely to see improvement is the software that controls the milling process. The development of more user-friendly software will make it easier for operators to create complex parts and components. In addition, we can expect to see better tool options and improved machine accuracy. As CNC milling technology continues to evolve, it will become an even more powerful tool for manufacturers around the world.

CNC Mills Will Be Used For A Wider Range Of Applications

A computer numerical control (CNC) mill is a machine that is used to create three-dimensional objects from a digital model. CNC mills are typically used in manufacturing applications, but they are also increasingly being used for a wider range of tasks, such as creating prototype models and even art. While CNC mills have been around for many years, advances in technology have made them more affordable and user-friendly, making them accessible to a wider range of users. As a result, it is likely that CNC mills will be used for an even wider range of applications in the future.

Demand For Skilled Operators And Technicians For CNC Milling To Increase

There is an increasing demand for skilled operators and technicians to work with Computer Numerical Control (CNC) milling machines. These machines are increasingly being used in manufacturing, as they offer greater accuracy and precision than traditional methods. As a result, those who are trained in their use will be in high demand. CNC milling machines can be used to create a wide variety of products, from small components to large-scale assemblies. In order to become a skilled operator or technician, one must undergo training in the use of these machines. This training can be completed at a vocational school or community college. Once trained, those who are looking for a career in CNC milling can find work in many different industries. With the continued growth of manufacturing, there will be an ever-increasing demand for those who are skilled in operating these machines.

The Cost Of Owning And Operating A CNC Mill Will Decline

In recent years, the cost of owning and operating a CNC mill has declined significantly. Thanks to advances in technology, these powerful machines are now more affordable and easier to use than ever before. As a result, more businesses are turning to CNC mills for their manufacturing needs. While the initial cost of purchasing a CNC mill can still be significant, the long-term savings can be substantial, meaning the question of how much does CNC milling costs might not matter much when compared to the potential returns. In addition to reduced labour costs, CNC mills require less maintenance than traditional machining equipment. As a result, the total cost of ownership and operation can be much lower over time. For businesses looking to reduce their manufacturing costs, investing in a CNC mill is an increasingly attractive option.

In Summary

It is clear that CNC milling will continue to be a popular technology in the coming years. As the technology improves, it will become more accurate and faster, making it ideal for a wider range of applications. There will be an increased demand for skilled operators and technicians to operate these machines. Additionally, the cost of owning and operating a CNC mill will continue to decline, making it more accessible for businesses and individuals alike. Have you considered adding a CNC mill to your shop?