As injection molding widely used in our daily life, more and more people have interesting about it, whatever their business is relative with injection molding or not. Imaging that when you looked a unique and beautiful brush pot, or bottle, you know that how they are produced and the principle they used. Isn’t it a feel that the relationship between you and modern society is closer?

There are 5 processes of making injection molds. After reading this article you will have a deeply understanding about injection molding.

1.Choosing Materials for Injection Molds Making

Injection molding can deal with different types of materials, like mental, liquid silicone, plastic. The commonest material it used is plastic. Choosing materials for injection molds making should base on your products. In this article, author will mainly introduce kinds of plastic materials.

ABS: acrylonitrile butadien styrene, is widely used in applicants and industries. It has superior toughness and strength, resisting against impact, temperature. This kind of materials are also easily be molded and colorfast.

Celcon ( Acetal ): also be known as polyoxymethylene (PDM), polyacetal or polyformaldehyde. This kind of material has outstanding toughness, excellent wear, creep resistance. It can against chemical solvent and easily to colorize. It be good at heat distortion, and has low moisture absorption.

Polypropylene: with chemical resistance, elasticity and toughness, fatigue resistance, this kind of material is the widest using in plastic injection molding. It is used in packaging, bottle caps or somethings like these.

Hips ( High-impact Polystyrehe ): it is widely used in printing applicants. It has good impact resistance, can be easily dealt by machine like cutting, has fine dimensional stability, outstanding aesthetic qualities, highly customizable surface.

LDPE: low-density polyethylene is a flexible type of plyethylene. It has superior moisture resistance, high-impact strength, good chemical resistance, and translucence, weatherproof. It can be easily processed with most methods.

2. Choosing A Reliable Injection Mold Maker

A reliable injection molds maker not only the place you take injection molds from, but the partner during your injection molding products making. Injection mold makers provide service during the whole sale process.

There are some suggestion for you to choose a reliable injection molds maker.

Choosing experienced injection mold makers with no less than two years sale. Injection mold makers who are enter this business with short time may provide discount for their customers, while they have not enough experience to deal any problem that may meet during the time of utilization of your molds.

Choosing the injection mold makers who make a close relationship with their customers. Close relationship with injection mold makers may provide the high-end technology of injection molding, which you can use them into your production.

3. Operating Principle of Injection Molding

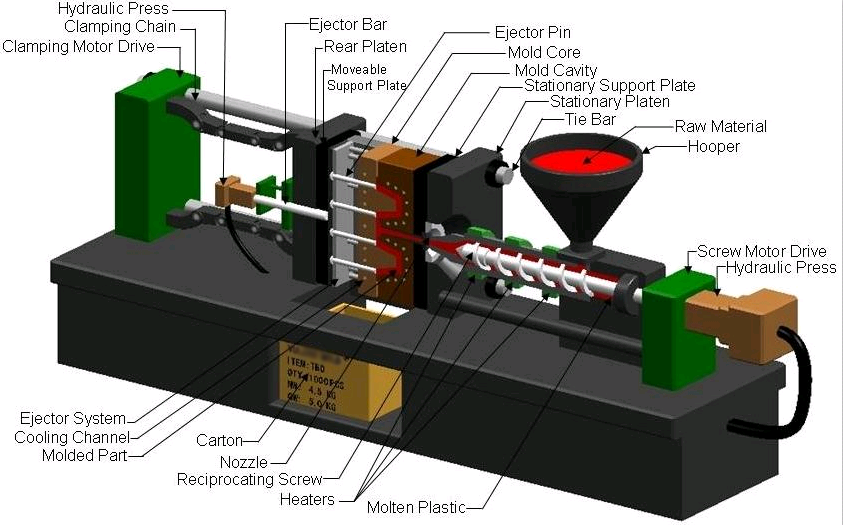

Every injection mold machine has these main parts: nozzle, charge, runner, pates, parts cavities and ejected pins. Molten materials were injected from charge, along nozzle to fully fill with runner and parts cavities. When it is cool, ejected pins, push them to make them leave away from molds. There are some operating principle of injection plastic molds.

Automatic production process. Powered by electric, injection mold works automatically. From injecting materials to push parts leave away from parts cavities, the process of mold producing is totally automatic.

Mass-production application. Injection molding with its one-machine-amount-produce feature, always be preferred by mass-production manufacturers.

4. Other Things You Should Consider When You Make Injection Molding

Considering injection mold manufacturers, materials, operating principle of injection molding. There are other things you should consider will be demonstrated. The cost and the product design.

Cost

Whatever your business are, the cost is the thing you must considering, either injection molding. With expensive up front cost, you must be sure that the profit your products took can break even the cost they made. Thus find the balanced point is very important for injection molding.

Product Design

Product design consider include two parts, first is part design, second is toll design. A suitable design will help you minimize cycle time, also avoid defects during production. With the feature of injection molding that it has expensive change cost, a right product design at first is necessary for your injection mold making. Thus production design is other things you should consider when you make injection molding.

5. After-service And Maintain of Injection Molding

For after-service and maintain of injection molding, different company has different strategy. When you chose a reliable injection molding maker, the after-service and maintain are easier. Any question you meet your partner can provide solve strategy for you, which is efficient and suitable for you. Connect with your injection molding maker closely, you will get the high-end technology about your product mold, which is reference for you to adjust your producing.

If you have other questions about injection plastic molds, contact with us!